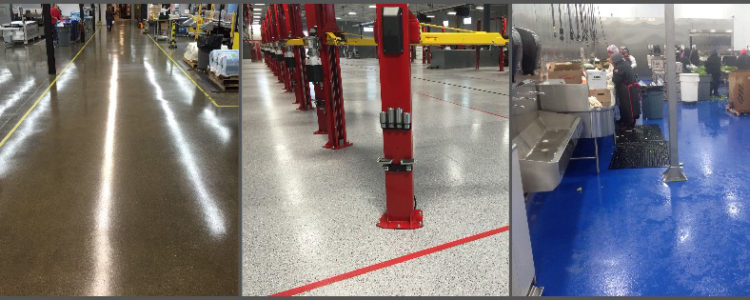

A Case Study on Slip Resistant Commercial Flooring

Customer Name: Curtis Products

Location: Bristol, Connecticut

Customer Needs: A proper floor coating that has ample grit in it as slip resistance is a must

On May 11, 2018, Curtis Products contacted manufacturer Florock to help provide a quote, and that due to the town of Bristol’s interest in this business’ relocation, that they needed this estimate as soon as possible. After a few hours of correspondence, as well as information on the current condition of the slab, New England Floor & Wall (NFW) was able to send out a proposal that same day.

New England Floor & Wall Process: Over the next two weeks, the president of NFW, Ken Bonney came up with a game plan to combat the oil saturated slab, as it had never been sealed. He made two site visits, the first being a preliminary visit to see how much the floor had been beaten up by the previous owner, which to his surprise, they had kept each area “clean” by machine shop standards. On June 20th, a second site visit was made to do preliminary moisture tests, all of which passed with ease. During this visit, Curtis Products president, Ron Weintraub, was able to choose how much slip resistance, which was his main concern. Ken had explained the pros and cons to the different levels of grit and warned Ron that the more slip resistance that is added; the harder it will be to mop the floors. He went on to advise on proper housekeeping and recommended that a walk behind scrubber be purchased.

On June 25th, roughly 45 days from first correspondence, NFW arrived at the building at 70 Halcyon Drive, Bristol, Connecticut to begin preparation of the floor. Although the floor was wide open, each area that housed the previous machines had been saturated over the years, leaving a film even after the prior owner had cleaned the entirety of the floor. With an industrial walk-behind scrubber from Tennant, NFW used an aggressive cleaner/degreaser along with an equally aggressive scrubbing pad to help eliminate any outside contaminants. It took two complete washes to eliminate the oil gloss, in which NFW was then able to start preparing the concrete.

Starting with a 2mm size of steel shot, the entire floor was “opened up.” This process helps to remove the top layer of concrete, as well as create a profile that allows for a deeper diamond cut with industrial walk-behind grinders. Following this process, an area was then prepared using an industrial walk behind grinder to allow for Ken to perform a multitude of floor samples, of which he was in direct contact with the manufacturer’s chemists creating a solution for the oil-laden floor. The following day, adhesion and pull tests were completed, and the best product for this floor was chosen.

After being able to sit overnight, several areas of embedded oil had resurfaced. The entire floor was then prepared a second time using large grinders equipped with blades that are impregnated with diamonds. A rigorous task to complete, over 1/8” of existing concrete was removed to eliminate the contaminated portion of the slab. Directly behind the industrial grinder, the concrete dust was removed using portable industrial vacuums. Given the summer heat wave conditions, doing this was essential as allowing the dust to sit for too long would cause the dust to re-attach itself to the floor. Once more, the floor was given an evening to rest, allowing for any oil that may still have been embedded to show through. These areas were cleaned and degreased once more, and the entire floor was ground for a second time before lunch.

Following a short break, the driven crew, equipped with spiked shoes and roller poles, made their way onto the floor to start the initial coat. It took a little over four hours from the first mix being poured out to complete. The following day, the crew came in and gave the entire floor a once-over with a large rotary buffer using screen. After vacuuming, and tack ragging, the crew installed a second, pigmented, coat to the floor. On the following day, the process of screening was repeated prior to the installation of a final coat. The final coat consisted of a high-performance urethane.

Conclusion: NFW used the maximum amount of grit allowed in this coat, which gave Curtis Products finished slip resistant commercial flooring that exceeded their expectations.