Our Services

New England Floor & Wall offers a full line of urethane & epoxy floor coating services for residential, industrial and commercial buildings. Our team uses only the highest quality products for your flooring. We’re committed to getting your job complete on time and on budget. Below you’ll find the various types of concrete floor types, methods & techniques we use:

Containment Area Flooring

Extreme chemical resistance. Cove base and burms protect surrounding areas. Spark proof, conductive or E.S.D. systems available.

Vapor Mitigation Systems

Stops or reduces pressure. Can be finished with any flooring type. Creates a barrier for concrete slabs to maintain safety & dryness.

Stamped Concrete

Textured patterns created to resemble wood, stone, brick or tile and often used for interior floors, patios, pool decks, driveways. Learn more here.

Waterproofing Membranes

Creates a impervious waterproof barrier. Vibration dampening. Excellent base coat for above-grade slabs. Excellent for moisture mitigation needs.

Thin Mil Flooring Systems

Perfect for light traffic areas. Stops concrete dusting. Great for light production areas. Easy to clean & resist abrasion.

Concrete Overlays

Decorative self-leveling concrete and cementitious overlays offer high performance in unlimited design options. Find out more.

Medium Build Floor Systems

For moderate traffic areas. Moderate abrasion and impact resistance. Spark proof, conductive or E.S.D. systems available. Great for production areas.

High Build Flooring

For heavy traffic areas. Great for resurfacing worn areas. Spark proof, conductive or E.S.D. systems available. Great abrasion and impact resistance.

Clear Epoxy Sealers

High-build protective film on concrete surface produces a hard, long-wearing, abrasion-resistant finish. Repels water. Learn more about epoxy sealers.

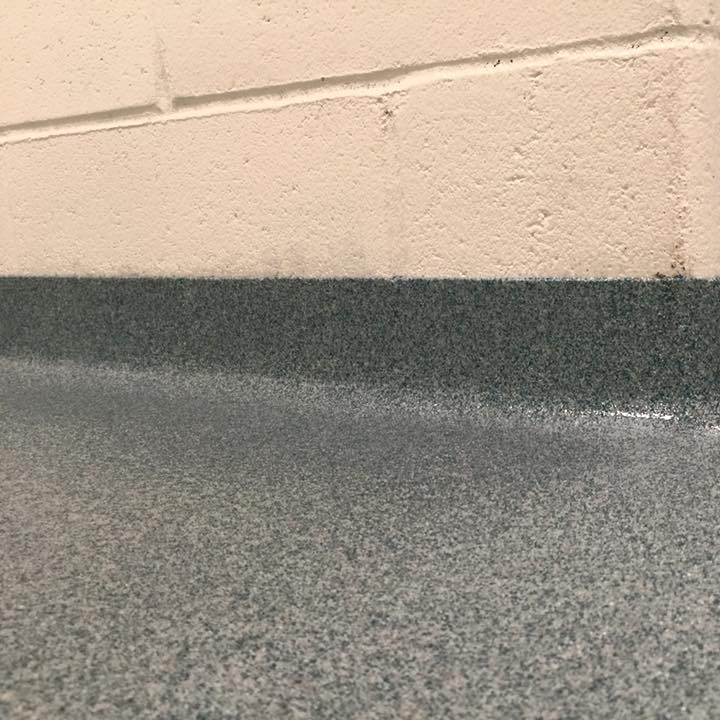

Cove Base

One of the unique advantages of seamless flooring is the ability to build an integral cove base. This integral cove allows you to create a virtual bathtub or shower base out of your seamless floor.

Advantages of a Cove Base

- Prevents water from going under the walls

- In chemical containment applications contains the chemicals to the coved area

- Makes it easy to clean and disinfect the edges of the floor

- Does not allow bacteria or insects to hide under the wall

- Gives the floor an attractive professional seamless look

- Required by government officials in many food and pharmaceutical applications

Clear Epoxy Sealers

Epoxy sealers form a high-build protective film on the concrete surface, producing a hard, long-wearing, abrasion-resistant finish. They also repel water and are available clear or pigmented, if you wish to add color. Most products impart a glossy finish.

Epoxy sealers are much harder than acrylics. Water-based epoxies bond well to concrete and provide a clear finish, but they are nonporous and do not allow trapped moisture to escape.

Epoxies are probably the best choice for concrete countertops and food-preparation areas. Typical applications for epoxy sealers include: floors in high-traffic and food-preparation areas; cement-based overlays, concrete countertops and more.